創新與循環經濟研究中心-中心起源

創新計劃彌補了研究與商業市場之間的差距。它幫助創新產品、服務和流程,保護環境的良好理念成為廣闊的商業前景廣闊的商業。創新是減少對環境的影響並更好地善用資源。這意味著開發更多能夠減少二氧化碳排放的產品、技術、服務和流程,且有效利用資源,促進回收再利用等。 創新有五個主要方面:

- 材料回收與再利用的過程

- 可持續建築產品

- 食品和飲料部門

- 水的使用效率,處理和分配

- 綠色企業

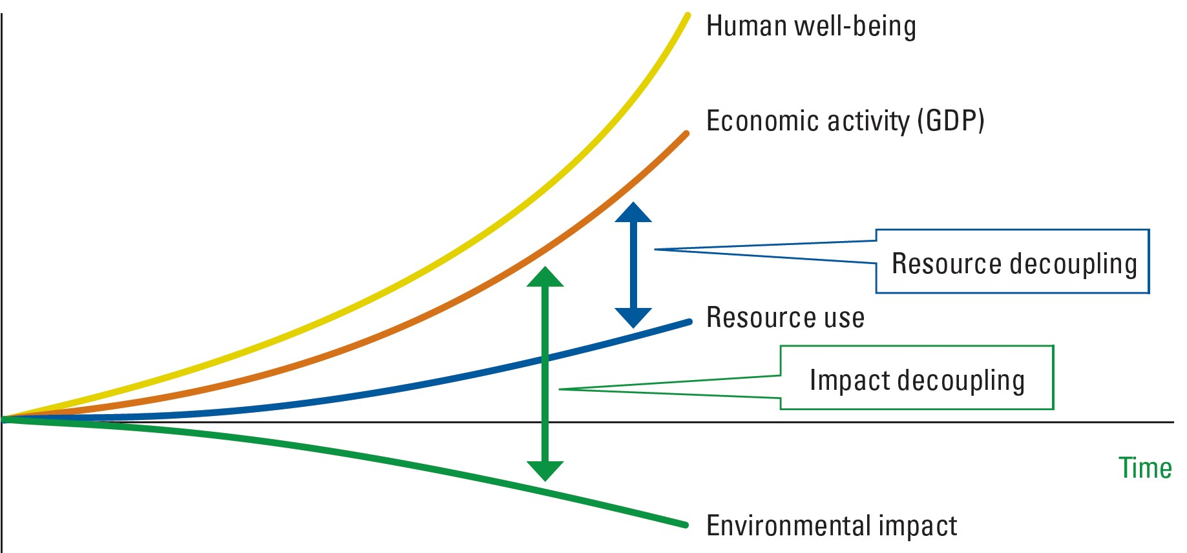

※在經濟活動上,所利用的資源和環境影響兩者必須和經濟脫鉤,進而促使社會經濟的成長及人類的福祉。

在公司層面上,越來越多的企業通過實施創新,顯示出價值鏈中確定的利潤機會。它幫助他們比競爭對手獲得了更顯著的優勢,並促進業務的增長,而各個相關市場的其他公司則停滯不前。中小企業實現全系統變革的潛力特別高,因為它們是屬於最多種類的公司,在發展中國家和新興經濟體中貢獻三分之二的正規就業機會。他們對環境和社會的影響是相對重要的,而與較大的公司相比,中小企業的小規模使得能夠更靈活的進行決策和創新變化的靈活性會更大。

在政府層面上,許多人意識到創新與生態的雙贏機會,能夠大大增強競爭力和經濟的發展。 在企業中,特別是中小企業創新的更能廣泛實施,通過有效的政策組合促進與推動,能有助於緩解資源限制和環境退化,改善社會福利和當地社區參與,並創造就業機會和吸引更多的財務資源。

創新的過程也提高了國家的知識和相關技能,同時提高了生產能力和經濟競爭力。例如,規章制度和經濟誘因的結合有效刺激投資和創新,有助於解決方案的新市場出現提供更完善的準備。創新主要市場在可再生能源發電、能源和材料效率、可持續性的水管理和流動性三方面。

創新也為整個社會帶來多種效益,通過減少使用危險和有毒化學品的環境惡化來減少對人類的健康風險。同時,通過創造就業機會以及為生產力的增長創造新的價值,並改善收入。這些可以是新興行業對可持續產品和服務以及供應商公司產生的就業機會,這些新興行業對投入產品與服務的需求也相對增加。另一方面,創新的解決方案也帶來了更重要的社會效益,例如改善並獲得更多能源,供水和衛生設施,這對發展中國家來滿足基本需求尤為重要。

因此,活躍的創新有助於減少經濟增長與資源消耗的相關聯,並有助於實現可持續發展目標。 這只能以綜合的方式和所有利益相關者共同努力,在私營部門的積極作用下才能夠實現。此外,企業通過價值鏈實現創新的解決方案,具有減少資源消耗、穩定的資源供應和價格的潛力,長期的生產率增長前景對人類發展至關重要。因此,促進創新是一個國家總體發展框架下的重要政策目標。

循環經濟(Circular economy)是藉由資源再生系統,由封閉的供應鏈循環 (Closed-loop supply chain),使得資源的再投入與零廢棄、零排放來達成資源永續 (Resource Sustainability) 的目標。循環經濟是一個永續發展 (Sustainable Development)的閉環式概念,並可與我們所處的環境和所擁有的資源共生再製造(Re-manufacturing)、再循環(Recycle)及再利用 (Re-use)的想法。循環經濟概念下所製造生產的每個產品都經過精心設計 (Re-design),並可用於多個閉環式資源循環來使用,成為新的生產週期(Life Cycle Assessment) 的原材料和素材。但必須藉由創新思維來創造新的商業模式 (Business Model),進而達成零資源量浪費 (Zero-Waste)及零排放 (Zero-emission),同時兼顧社會、環境及經濟議題 (Triple-Bottom-Line)。循環經濟是帶動消費成長 (Consumption growth)及投資(政府及私人投資)成長 (Investment growth),而成為國家經濟成長之新動能(Economic Growth)。循環經濟強調,大多數關注在以下四個基本區塊:

- 循環產品設計(重點領域 - 新設計)

- 新商業模式(生產再製造)

- 反向循環和串聯(消耗 - 使用,再利用,修復)

- 系統條件(廢物管理)

在產品設計階段,當地和地方當局部門可以透過採購資源節約型、耐用性高、易於修理或升級的產品和解決方案,並回收或再利用。這種鼓勵市場開發的解決方案,使他們不僅更容易獲得,而且對其他使用者來說也是更實惠的。以下是產品設計階段的三個主要特點:材料選擇(設計更容易拆卸/產品的靈活性),模塊化/組件化(產品的設計從一開始到最後),標準化/規格化(生產過程效率的最小化浪費)。

以生命週期為視角。將廢物變成更多資本而不是僅是單純減少廢棄物。 從線性經濟(從搖籃送到墳墓)轉向更循環的經濟(從搖籃到搖籃)需要新的商業模式,即新的消費者行為模式和將廢棄物轉化為資源的新解決方案。進一步看待生產階段,城市和地方可以與其他利益相關者合作,促進原材料的可持續性採購和資源循環的不同模式,如工業共生,化學品租賃或再製造。

高效率,更好的質量收集與處理系統,對生命週期終結產品進行有效分割,對於經濟上的嶄新循環商業模式至關重要。在循環經濟的閉環供應鏈建立相關功能和基礎設施是至關重要的。地方和當局也有能力積極影響民生,企業和組織的消費模式。這可能包括教育和宣傳運動,促進分享經濟方式,以及鼓勵再利用和修復。 廢棄物收集系統有三個成功因素(1)用戶滿意/使用者易於使用的(2)合宜的客戶和報廢專員(3)能夠保持回收材料的質量。

有效的跨行業和跨部門合作是大規模建立循環系統的必要條件。市場機制必須發揮主導作用,其決策者,教育機構和意見領導者都能從其中得到好處。廢棄物收集和回收是市政當局最常與之相關的責任。改善廢物的收集系統可以是循環經濟的第一步,但許多城市和地方也在考慮擴大生產者責任或高質量的回收利用和廢物的生物處理(如生物精煉,堆肥或厭氧消化)。 此外,系統優化主要集中在以下發展因素和加強交叉價值鏈協作(1)跨價值鏈業務模式(2)材料流動的能見度(3)行業標準和配對機制。

創新與循環經濟的作用遠遠大於單純地減少浪費和增加廢棄物的回收再利用,通常通過生態設計來探索創新在早期產品生命週期閉環供應鏈中的作用,並開創和建立激勵機制使用新的商業模式,讓資源更有效利用。

循環經濟是指透過產品與流程的整體設計、目的或有助於恢復的工業經濟,其重點是搖籃到搖籃的原則和材料的可持續性。資源用於實現高品質設計,而不會污染生物圈。循環經濟將有利於所有企業,特別是中小企業,並確定使用激勵措施來刺激與促進必要的創新,從綠色政府採購到完成單一市場。特別是,在提供服務而不是單單的製造產品方面,可能會發現更多商業機會。

創新是新的商業模式,而不僅僅是技術方面。產品設計沒有一種普遍適用的解決方案,生態設計和綠色政府採購的現有框架可以通過對可修復性,耐久性和可回收性的要求來提高材料效率。關於原材料二次利用,數位科技可以提供有關產品可回收材料的即時線上資訊,跟踪庫存和流量,提高可追溯性,促進更加透明的擴大生產者責任制。從消費階段來看,生態設計,歐盟生態標籤和能源標籤等現有工具可以解決耐用性和可恢復性。創新可以改善零配件的存取,以及維修服務、訊息和手冊,並改進產品使用的壽命訊息。創新還可以幫助設計產品有更好的耐用性,材料和成分化學品的可再循環性,並提高原始和回收材料的可追溯性。

循環經濟側重於個人,公司和政府有效和可持續性的資源利用。未來將在長久的過程中為我們的社會提供服務,並物盡其用和使用循環再造的產品,使人們減少原材料的使用,而不會去耗盡地球的自然資源。