Institute of Innovation and Circular Economy

The innovation initiative bridges the gap between research and the market. It helps good ideas for innovative products, services and processes that protect the environment become full-fledged commercial prospects, ready for use by business and industry. The innovation is about reducing our environmental impact and making better use of resources. This means developing products, techniques, services and processes that reduce CO2 emissions, use resources efficiently, and promote recycling and so on. There are five main strands of this initiative:

- Materials recycling and recycling processes

- Sustainable building products

- Food and drink sector

- Water efficiency, treatment and distribution

- Greening business.

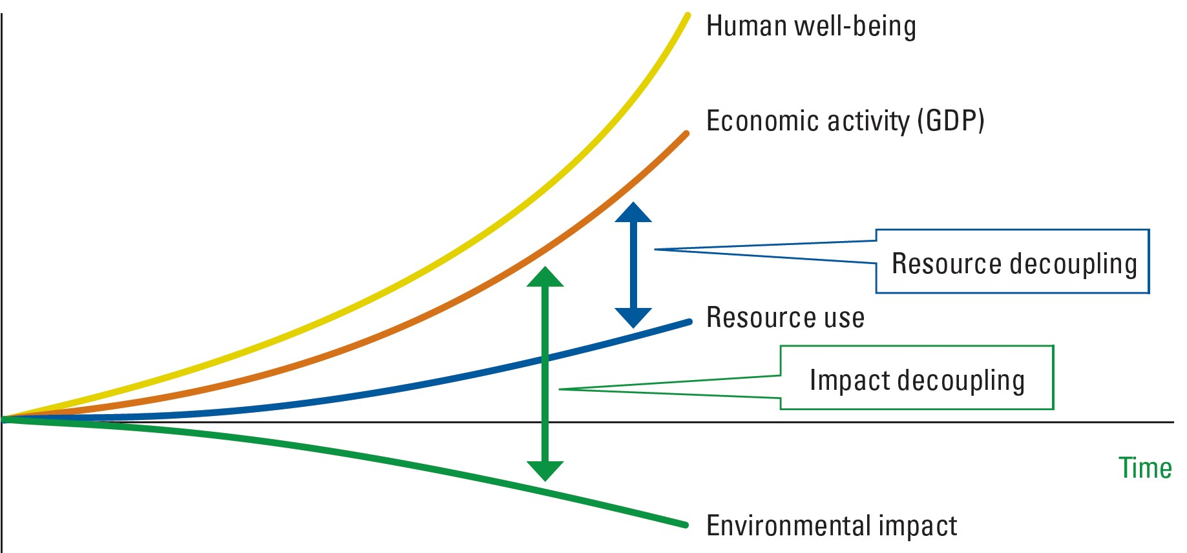

※※In economic activities, both the resources used and the environmental impact must be decoupled from the economy, thus contributing to the socio-economic growth and human well-being.

At the company level, a growing number of businesses have demonstrated profit opportunities identified along the value chain through implementing innovation. It has helped them to achieve a significant advantage over their competitors and to generate business growth while others in the respective markets have remained stagnant. The potential of small and medium sized enterprises to bring about system-wide change is particularly high as they are the most numerous type of companies and contributing to two thirds of formal employment in developing and emerging economies. Their impact on both the environment and society is significant, while their small size enables more agile decision-making and more flexibility for eco-innovative changes compared to larger companies.

At the government level, many have realized the win-win opportunities for innovation to significantly enhance competitiveness and economic development. More widespread implementation of innovation in companies and especially small and medium sized enterprises pushed and pulled by effective combinations of policies can contribute to the alleviation of resource constraints and environmental degradation, improvement of social welfare and local community engagement, job creation and attracting financial resources.

The process of innovation also enhances in country knowledge and skills, while increasing productive capacity and competitiveness of the economy. As an example, a combination of regulatory framework and economic incentives has spurred investment and innovations which paved the way for the emergence of new markets for innovative solutions. Innovation in the areas of renewable energy generation, energy and material efficiency, sustainable water management and mobility.

Innovation also holds multiple benefits for society at large by reducing health risks from environmental degradation from the decrease in the use of hazardous and toxic chemicals. At the same time, it can improve income through job creation and from generating new sources of value for productive growth. These can be jobs, generated by emerging industries for sustainable products and services as well as in supplier companies following the higher demand for inputs to these emerging industries. Innovative solutions also bring crucial social benefits such as improved access to energy, water and sanitation which is particularly relevant for developing countries to meet basic needs.

Innovation, therefore, actively contributes to decoupling economic growth from resource consumption and helps achieve the Sustainable Development Goals. This can be only achieved in an integrated way and with concerted efforts of all stakeholders with the active role of the private sector. Innovation applied by businesses with solutions scaled through their value chains has the potential to reduce resource consumption and stabilize the resource supply and prices for longer term prospects of productive growth, which is important for human development. Thus, the promotion of innovation can be an important policy objective within the overall development framework of a country.

The conventional understanding of economic activity is based on a linear model. Natural resources are extracted and transformed into products; the products are bought and used by consumers who, as soon as the products no longer fulfill their needs, throw them away. However, this model ignores the high economic, environmental and social costs related to the extraction, transformation and disposal of resources, and is therefore unsustainable in the long term. A CE offers an alternative model where the value of products, materials and resources is maintained for as long as possible and waste is significantly reduced or even eliminated. Keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life. Focused on “closing the loops”, a CE is a practical solution for living within our planetary boundaries. The transition towards a CE affects different policy areas, ranging from mobility, agriculture, land use and waste management, to business development and consumer education, concerning actors across all sectors and levels of governance. A CE is not something that any single institution or company can do alone. By its very nature, CE fosters connections across individual stakeholders and sectors. However, a transition to a CE is both a necessity and an opportunity, with the potential to offer long-lasting economic, environmental and social benefits. CE highlights that the majority focus on four essential build blocks.

- Circular Product Design (Focus Area-New Design)

- New Business Model (Production Remanufacturing)

- Reverse Cycles and Cascades (Consumption – Use, Reuse, Repair)

- System Conditions (Waste Management)

When it comes to the product design stage, local and regional authorities can lead by example in purchasing products and solutions that are resource-efficient and durable, can be easily repaired or upgraded and finally recycled or reused. This encourages the market to develop such solutions and makes them not only more accessible, but also more affordable for other actors. The following are three features of the new design phase: material selection (Design for easier disassembly/Design flexible), modularization (Design to last), and standardization (Production process efficiencies to minimize waste).

Taking the lifecycle perspective. The waste builds capital rather than reduce it. Moving from a linear (Take-Make-Dispose) to a more CE (Make-Use-Return) calls for new business models, new modes of consumer behavior and new solutions for turning waste into resources. Looking further at the production stage, cities and regions can work with other stakeholders to promote sustainable sourcing of raw materials and different modes of resource circulation, such as industrial symbiosis, chemical leasing or remanufacturing.

Cost efficient, better quality collection, treatment system with effective segmentation of end-of-life products will be crucial to enable economically attractive circular designs. Building up the capabilities and infrastructure to close the loops is critical. Local and regional authorities are also well positioned to actively influence consumption patterns of households, businesses and organizations. This might include education and awareness campaigns, promoting the sharing economy approaches, as well as encouraging reuse and repair. There are three success factors for collection systems (1) Be user-friendly (2) Be located in areas accessible to customers and end-of-life specialists (3) Be capable of maintaining the quality of materials reclaimed.

Effective cross-chain and cross sector collaboration are imperative for the large-scale establishment of a circular system. Market mechanisms will have to play a dominant role, but they will benefit from support by policy makers, educational institutions and popular opinion leaders. The waste collection and recycling are two of the responsibilities most often associated with the municipal level. Improved waste collection can be a first step towards a CE, but many cities and regions are also looking into extended producer responsibility or high-quality recycling and biological treatment of waste (e.g. bio-refining, composting or anaerobic digestion). Furthermore, system optimization that the main focus on the following factors of development and reinforce cross-value chain collaboration (1) Cross-value chain business models (2) Visibility of material flow (3) Industry standards and match- maker mechanisms.

Innovation is critical for new business model, not just technology. There is no one-size-fits-all solution for product design, and that existing frameworks for eco-design and green public procurement could improve material efficiency through requirements on reparability, durability and recyclability. When it comes to secondary use of raw materials, digital technology could provide online information about recyclable materials in products, keep track of stocks and flows, improve traceability and facilitate more transparent extended producer responsibility schemes. Looking at the consumption phase, existing instruments such as eco-design and the EU eco-label and Energy Label, could address the durability and reparability. Innovation could improve access to spare parts, as well as repair services, information and manuals – and improved information on lifespan of products. Innovation could also help design for greater durability, recyclability of materials and constituent chemicals, and promote traceability of virgin and recycled materials.

CE and the role of innovation ranged far wider than simply reducing waste and increasing recycling, often touching on the role of innovation in closing the loop earlier in product lifecycles through eco-design, and in pioneering and incentivizing new business models that use resources more effectively.

The CE refers to an industrial economy that is, by design or intention, restorative and which focuses on cradle-to-cradle principles and materials sustainability. Resources are used to enable high-quality design without contaminating the biosphere. The CE will benefit all business, especially small and medium-sized enterprises, and identified the use of incentives to stimulate the necessary innovation, from green public procurement to completing the single market. In particular, commercial opportunities may be found in providing services rather than manufacturing products.

The CE focusses on efficient and sustainable resource use by individuals, companies, and governments. The future is providing services to our citizens in a long-term process and products that are used and re-used time and time again, so that people reduce the use of raw materials and don’t deplete the earth’s natural resources.

There have the following of six ways to address waste and improve incentives: regenerate (repair), share (reuse), optimize (to find efficiency gains), loop (recycles), virtualize (use software on generic machines rather than manufacturing specialized machines) and exchange (replace traditional materials with recoverable, renewable or bio-based ones).